After making my first set of scales and researching various different extant samples, I became interested in making a set inspired by a particular style which featured a silver finish with exposed gold color in the pans. The first example of the style I ran into was this set found near Trondheim.

Looking at the bowls, it seemed to me that they were bronze that was somehow coated or plated and then scratched off to expose the material below. The discoloration of the alloy on the edges of the bowl and in some of the exposed area, as well as the fact that the gold colored areas look to be scribed into the bowls pointed to the fact that the bowls were a base metal, rather than gilding on silver, for example. My assumption was that the bowls were coated in tin and then scribed or scratched away to give the two-tone effect. Looking further I found that indeed the scales below, found at Lø, Steinkjer, and were a tin plated copper alloy (Pettersen, A. M. H. (2014). Insular artefacts from Viking-Age burials from mid-Norway. A review of contact between Trøndelag and Britain and Ireland.).

Additionally, in March of 2023 I was fortunate enough to also stumble upon a third scale set with similar decoration on the bowls during a visit to Copenhagen after I had decided that I wanted to make something like these. In the National Museum of Denmark’s viking exhibit, I found this set, with very similar bowls, but the balance itself did not appear to fold like the other designs.

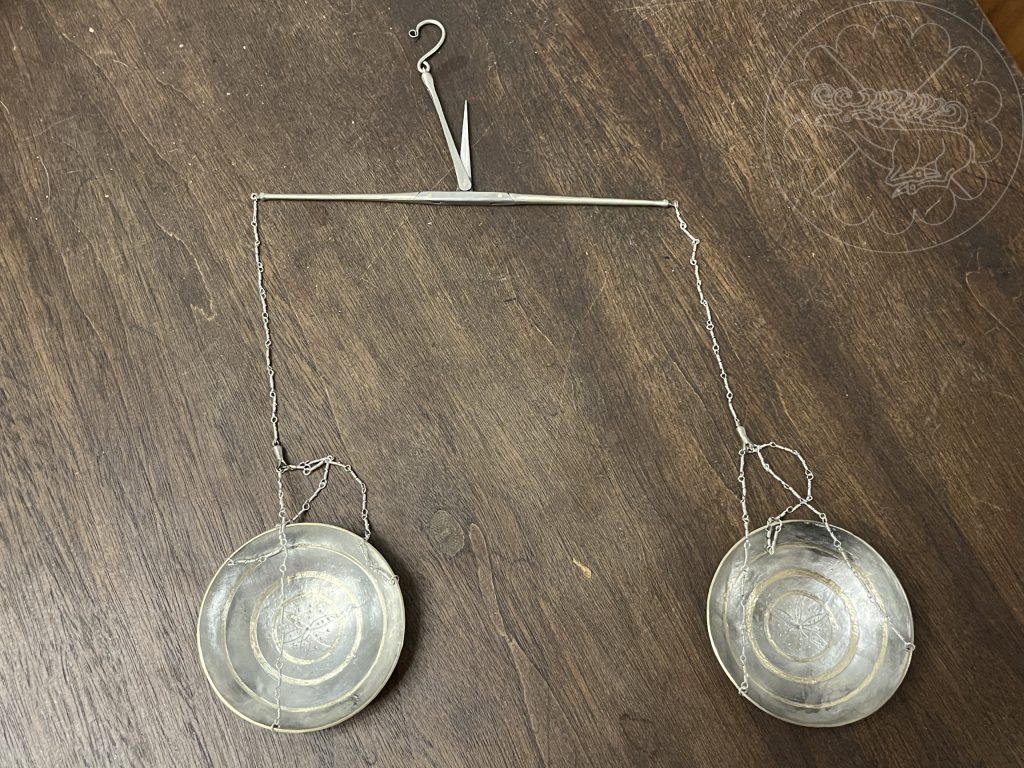

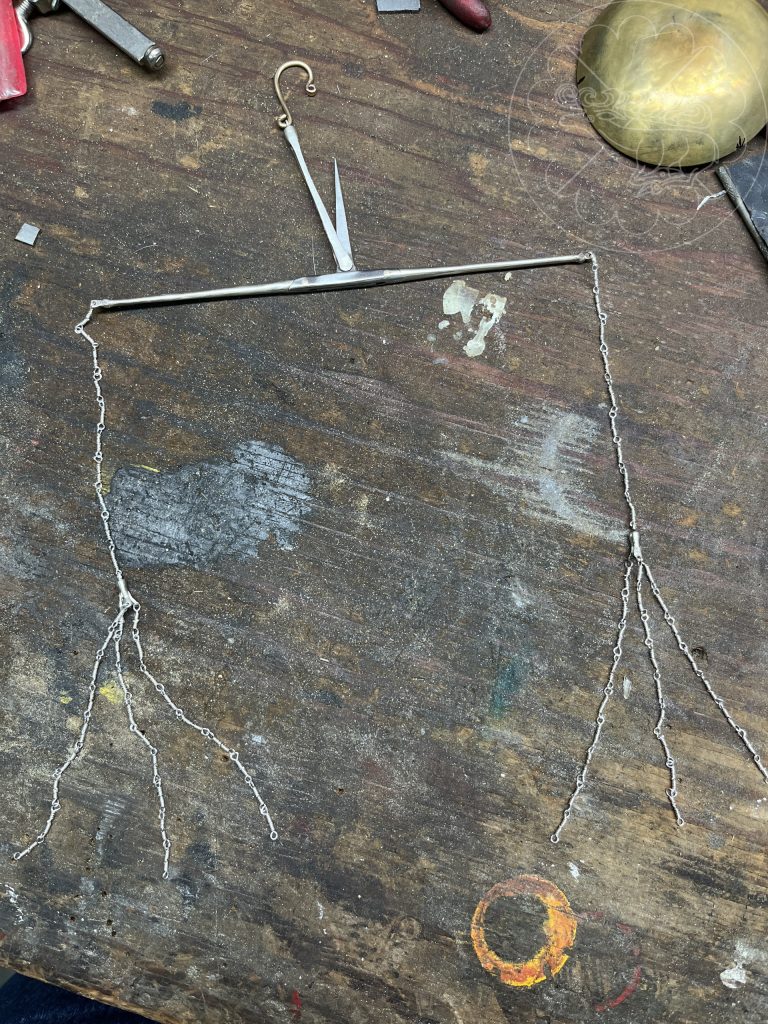

The body of the balance and the chain dividers are fabricated from nickel silver, and the pans tinned brass. The chain is made from 26 gauge tinned copper wire.

With all of this in mind I then needed to learn how to plate the bowls with tin. Historically, tin was used to coat base metals for both purely aesthetic reasons (to give the appearance of silver) and also to give a protective coating to cookware that may be exposed to acidic solutions that can form copper carbonate which is poisonous. There are a number of way tin was deposited onto other metals, but simplest is to heat the metal and then wipe the tin onto the metal where it melts and coats the surface. Tin has a really low melting point (~450°F or 232°C) compared to copper alloys, so the bowls can be heated easily to tin’s melting point without any danger of melting the bowls themselves. The process uses sal ammoniac powder (ammonium chloride/nausadar) as a flux during the coating process. The brass is heated, the sal ammoniac powder is added, and the tin is then rubbed on the surface to melt, and then spread over the surface with a cotton cloth. I wish I had spent a little more time practicing before jumping in to the scale’s bowls because the initial results on the insides of the bowls are not as uniform as the bottoms which I did later, but overall the results achieved what I was shooting for.

Although none of the extant scales had cases associated with them that I found, I did want to make one to protect them and allow them to be carried easily. The case I made is also from nickel silver with some details, particularly the clasp, inspired by this case found in Gotland.

Here is the case in process and just after finishing..

And finally, below are images of the completed scale set.