Throughout the history of the trade of precious metals, having means to judge the metal’s purity has been essential to ward of forgery and adulteration. While various chemical and/or heat-based methods have been known for hundreds of years, a simpler nondestructive method using a touchstone is probably much older. The metal in question would be rubbed on the touchstone and compared to a rubbing of a piece of known quality, examining the color for changes indicating contamination or replacement with base metals. Although touchstones of many shapes and sizes have been identified by chemical analysis of marks left on the surface, the majority are hand worked oblong shapes with a rectangular cross section and a hole for suspension drilled in one end.

Hundreds of these small, elongated stone artifacts have been found as personal items in high status graves. Although many are identified as whetstones, another use for similarly shaped objects, touchstones were typically darker in color, and possibly more finely grained. Since visible traces of marks on stones are rare and intensive modern chemical analysis is required to distinguish between touchstones and whetstones, the original use of many of the found stones is questionable. A good source of information on touchstones is the following article: Ježek, M. (2013). Touchstones of archaeology. Journal of Anthropological Archaeology, 32(4), 713-731.

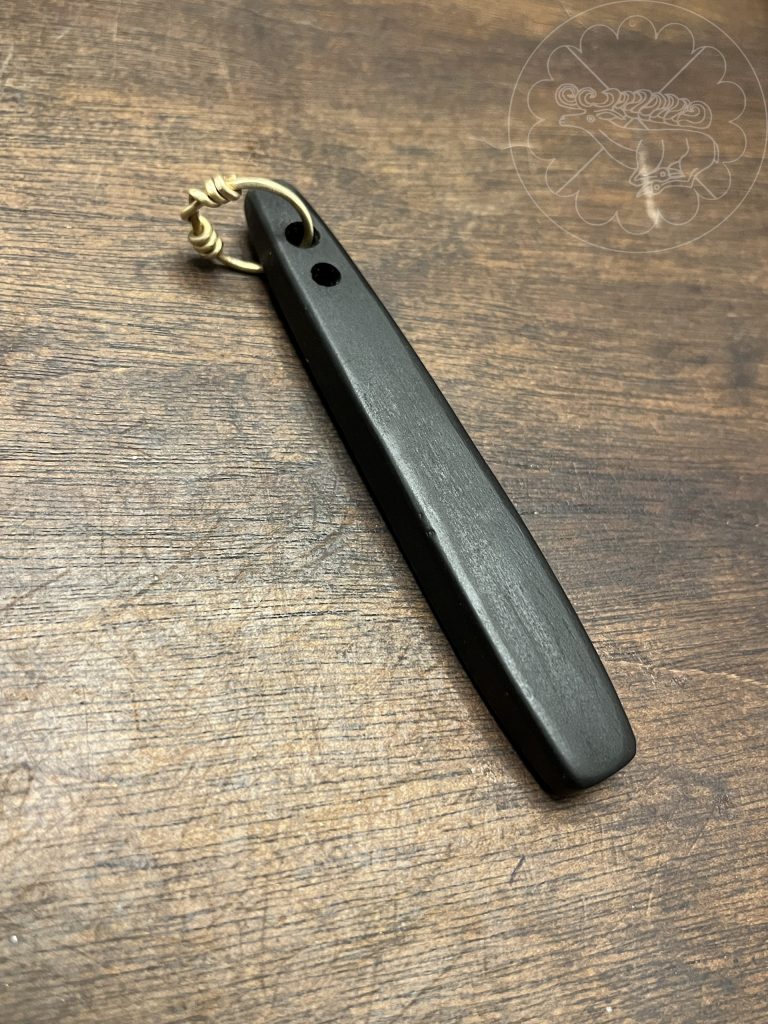

Some of the stones have been found with intact metal suspension loops, a few even comprised of precious metals such as silver wire.

To complement the viking scales I’ve made, I thought it would be good to have a touchstone of my own. The elongated ovalized shape is based on a find from Pommerania (see Wadyl, S., & Karczewski, J. (2021). Touchstones from Early Medieval chamber graves in Ciepłe, Eastern Pomerania. Sprawozdania archeologiczne, 73(2)) and I’ve kept one of the first in that shape as my personal touchstone.

In learning to shape them I had ample raw material, so I continued to make others of various shapes and sizes. The touchstones here are made from slate and lydite, the lydite being slightly darker of the two. The dark uniform color allows the streaks from the metal to be seen and compared easily. Rough shaping was done with a tile saw, and detailed shaping was done with various grinders, sanders, and polishers.